Iranian refinery using home-made catalysts, molecular sieves

An Iranian gas refinery has started using catalysts and molecular sieves manufactured by domestic companies as part of efforts to cut back reliance on foreign suppliers amid sanctions that restrict Iran’s access to technology and equipment from overseas.

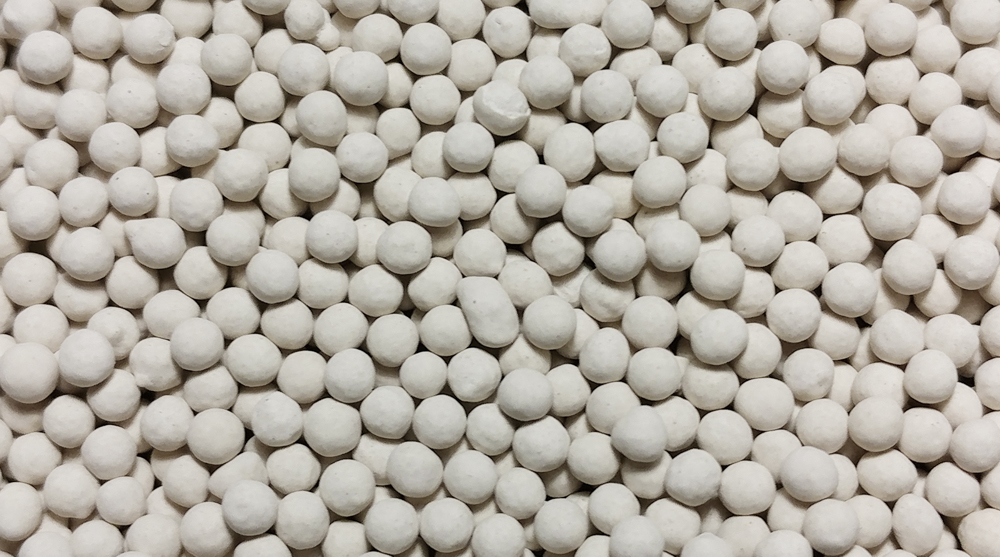

CEO of Ilam Gas Refinery Company Rouhollah Nourian said on Monday that the refinery had deployed Iranian-made molecular sieves in its demoisturization unit, adding that alumina and titanium catalysts needed in sulfur and active carbon recovery systems of the refinery had also been supplied by Iranian companies.

Nourian told the Iranian Oil Ministry’s news service Shana that Ilam refinery, located in western Iran, used to rely on foreign suppliers of catalysts and molecular sieves for its routine operations before the products were manufactured inside Iran.

He said the refinery has purchased and used 21 products, including 16 equipment items, that have been manufactured for a first time inside Iran.

Facing a raft of American sanctions that target its energy sector, Iran has increasingly relied on domestic manufacturers to supply machinery and parts needed in its massive oil and gas projects.

The government has offered financial support to local companies that come up with innovative solutions to offset the impacts of the sanctions on Iran's oil and gas industry.

Experts say the policy has paid off as Iran has been able to maintain its oil and gas output at levels seen before the US imposed its sanctions on the country in 2018.

US, Israel resorting to ‘soft warfare’ against Iran after June defeat: Top general

VIDEO | Hundreds brave wind and cold to show solidarity with Gaza in Berlin

Israel kills more Palestinian civilians in Gaza amid ceasefire violations

VIDEO | Paris protest condemns US aggression against Venezuela

Pope Leo says Venezuela must remain an independent country

VIDEO | Germans condemn US aggression against Venezuela

VIDEO | Israel withholds fate of disappeared Palestinians

VIDEO | Venezuela's interim president will continue same policies: Analyst

This makes it easy to access the Press TV website

This makes it easy to access the Press TV website